Refining/Chemical Processing

Blasch understands the intricacies of your processes and has developed integrated solutions that are designed to improve yield and reliability. Our numerous patented systems redefine refinery refractory applications, improve processes and lower costs.

MARKET MANAGER

Tim Connors, Director of Business Development, Blasch Global Solutions

+1-518-436-1263 Ext. 105

Tim Connors, Senior Market Manager, has been with Blasch Precision Ceramics since 1995. He holds a Master of Science degree in Advanced Technology. A Mechanical Engineer by education, he has configured abrasion resistant solutions, molten metal linings, flow control systems, high temperature firing fixtures and chemical and corrosion lining systems using Blasch’s unique forming method and custom materials. His area of expertise is in custom wear applications for the Power Generation, Mining, Industrial Process Heating and Heavy Industrial Processing industries. He currently manages the Energy & Chemical Markets, which include Refining/Chemical Processing, Mining, Heavy Industrial Processing, Industrial Process Heating and Power Generation. In addition to that he holds a role in Business Development for our Global Specialty Products division.

Sulfur Recovery and Thermal Oxidizers (TOX)

Blasch has been serving the sulfur recovery and thermal oxidizer (TOX) market for over two decades and in this time has developed a number of patented innovations that have allowed operators to run longer campaigns with greater reliability while saving energy with lower emissions. Our unique forming process allows us the freedom to design virtually without constraint to optimize the end user’s process.

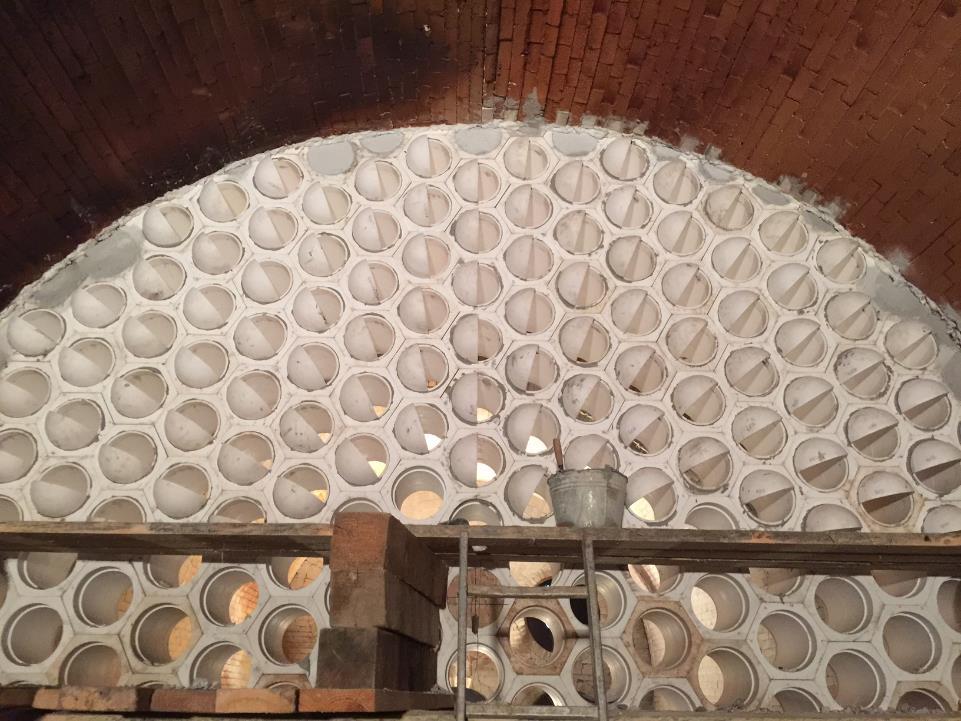

Steam Methane Reforming

Reformers, syngas reactors and fired heaters are high temperature enclosures designed to provide the maximum amount of high quality heat at the lowest operating cost to a variety of chemical processes. These are energy intensive pieces of equipment, with critical reliability implications, and Blasch has developed products for these areas that increase reliability, reduce installation time, and lower the overall thermal mass, and therefore, the cost to operate.

Fluid Catalytic Cracking

Fluid catalytic cracking involves the breaking down of the larger, heavier, and more complex hydrocarbon molecules into simpler and lighter molecules. Fluid catalytic cracking, by definition, involves the use of abrasive catalysts at high pressures in fluidizing environments, high temperatures, and steam. Blasch has significant expertise in all of these environments and has developed a number of abrasion-resistant silicon carbides that can stand up to these conditions and may be cast into a variety of close tolerance, complex shapes that can be used for everything from the air grid nozzles to large vessel linings. Learn more about our ceramic solutions for common wear problems in FCCUs.

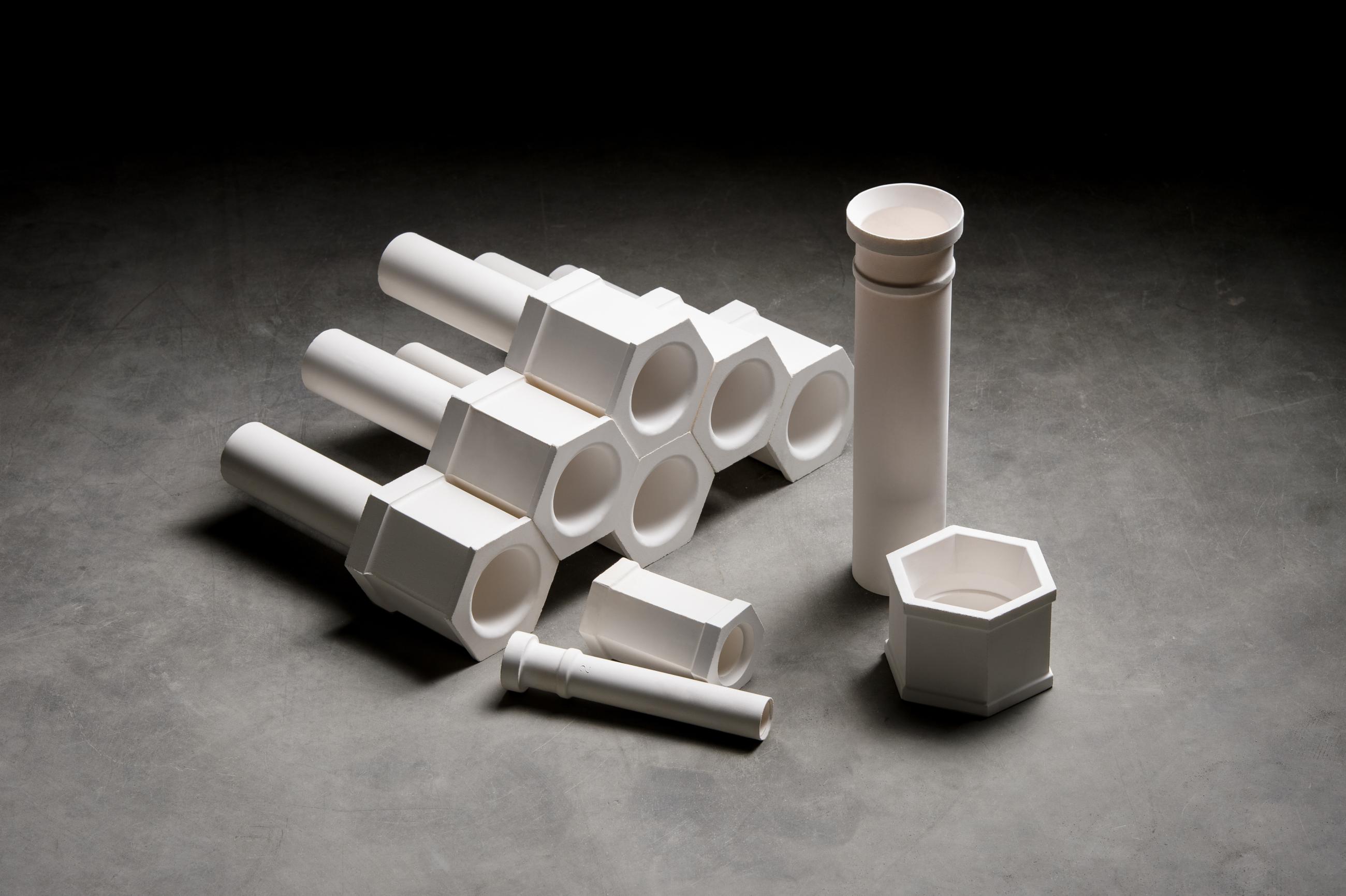

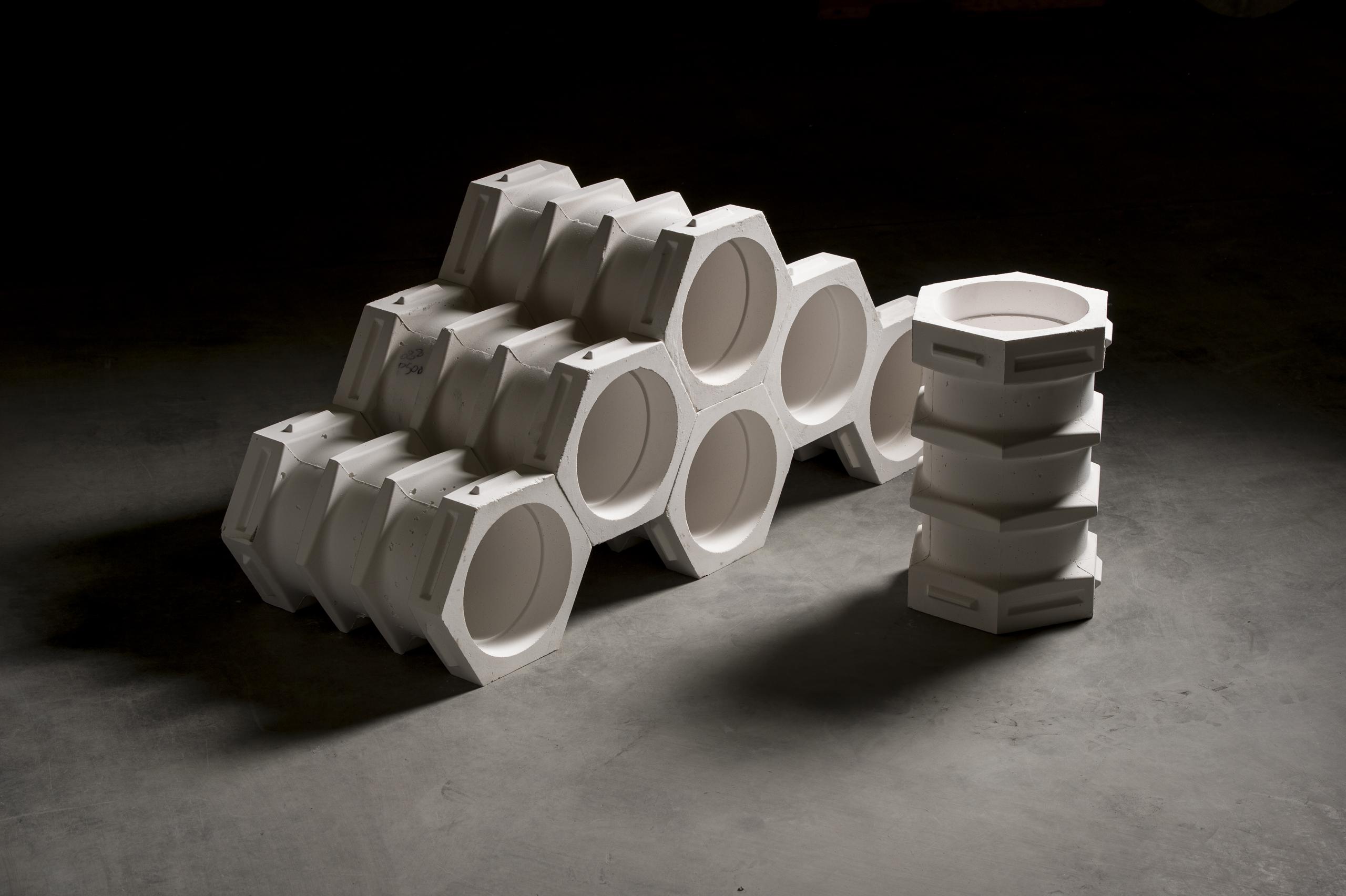

Secondary Reforming/GTL/Syngas

Conditions in secondary or autothermal reformers, gas to liquids and syngas processes can be quite extreme, with heavily reducing hydrogen and carbon monoxide atmospheres. The materials selected for use in the reactor or waste heat boiler section must be of the highest purity alumina, yet maintain excellent thermal shock resistance. The Blasch process allows for the manufacture of 99%+ alumina that is not fine grained, fully dense, or sintered and therefore retains the excellent thermal shock performance of the rest of the Blasch compositions.

Sulfuric Acid Production

Blasch serves the sulfuric acid market and offers highly engineered products that have been serving the sulfur recovery market for over two decades. Blasch components have allowed Licensors, EPC’s and Process Engineers to offer greatly improved reliability, NOx guarantees, better mixing and combustion all at a lower overall cost to the end user. Our unique forming process allows us the freedom to design virtually without constraint to optimize the end user’s process.

TiO2 Production

Blasch has extensive global experience in solving every day challenges of modern TiO2 production, particularly in the finishing process, often pioneering new high temperature abrasion and corrosion resistant solutions. Blasch Altron ™, Oxytron™ and Nitron™ silicon carbide were designed to improve plant efficiency, reliability and environmental performance. Blasch offers advanced silicon carbide solutions for wear and structural applications that often replace a metallic piece. Wear resistant micronizer linings, hot tickle piping, valves, reactor linings, chlorinator parts and other shapes are available.

Flaring/Chemical Destruction

Flaring systems in refineries and chemical plants process a wide range of difficult chemicals and the components in these systems are highly susceptible to the effects of high temperatures and thermal shock. For this harsh environment, Blasch offers a range of thermal shock resistant compositions particularly suited for this unforgiving environment. Our highly engineered solutions offer the maximum amount of protection for a wide range of aggressive chemicals.

Steam Cracking

Steam crackers are high temperature enclosures designed to provide the maximum amount of high quality heat at the lowest operating cost to a variety of chemical processes. These are energy intensive pieces of equipment, with critical reliability implications, and Blasch has developed products for these areas that increase reliability, reduce installation time, and lower the overall thermal mass, and therefore, the cost to operate.

Carbon Black

Carbon black reactors operate at perhaps the highest temperatures of any piece of equipment in the chemical industry. Further, the quench section subjects refractory linings to severe thermal shock and stress, which can lead to cracking and premature failure of the refractory lining. Blasch precast components have the abrasion resistance necessary to survive this inhospitable environment as well as the thermal shock resistance to offer a long-term reliable solution to current approaches.