Image

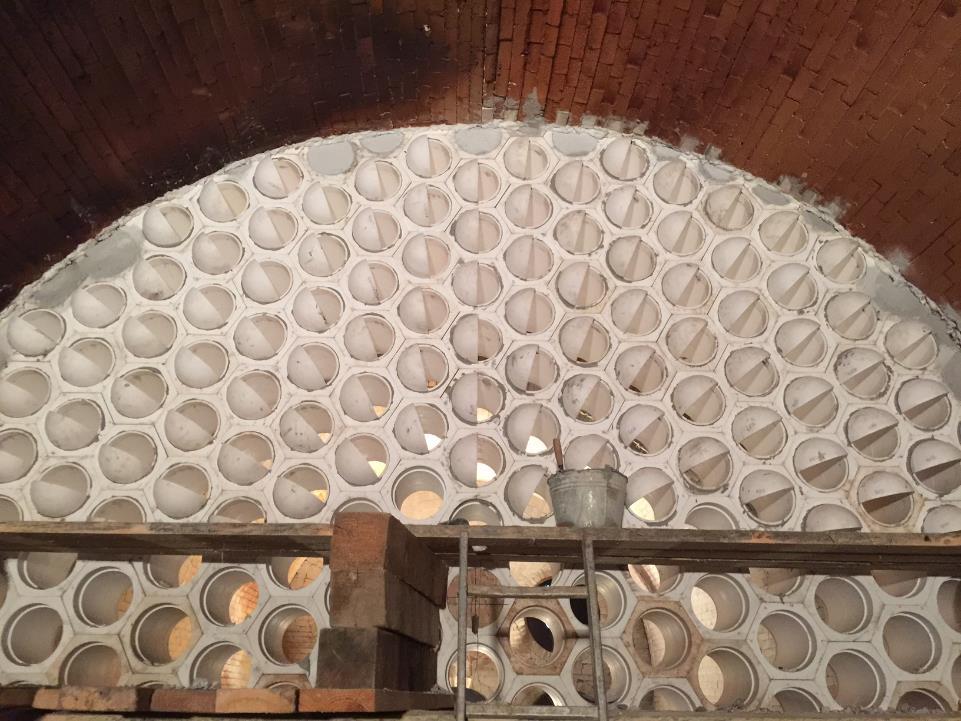

Mullite

Blasch offers a range of mullite compositions for use in some of the more difficult industrial environments. It is known for its high temperature hot strength, resulting in excellent resistance to hot deformation under load (creep) and excellent thermal shock resistance. With its incredible structural stability, this material is able to remain chemically inert in most environments.

ADVANTAGES OF MULLITE

- Tremendous structural stability

- Excellent thermal shock resistance

- Remains chemically inert in most environments

Related Products

Following is a list of products that we supply to industries worldwide including, but not limited to: