InterLok™ Segmented Crucible Lining Systems

Blasch contributes to the successful operation of larger induction furnaces (greater than 1,000 lbs.) around the world employing precision InterLok Segmented Crucible lining systems. Available in a variety of premium refractory materials, these systems are individually engineered and offer each user the utmost in control of melt chemistry, the lowest levels of ceramic inclusions in finished product coupled with easy installation and predictable campaign life. With sizes from 650 pounds to 15,000 pounds, a complete review of the benefits of the InterLok lining systems should be investigated by any large alloy producer or atomizing plant.

Customize Your System

We offer comprehensive customization of the InterLok system to meet the unique requirements of your operation. Our solutions include pre-cast integrated spouts and spout extensions, ensuring seamless flow control and durability. We also provide bottom and side through holes for bottom pour systems, designed to enhance efficiency and precision in metal casting applications.

Whatever your specific needs, Blasch’s engineered solutions deliver reliability, consistency, and superior functionality.

Improve Your Process

The InterLok lining system has been engineered to offer several advantages to users:

• Improved metal quality with fewer impurities

• Reduced spalling and erosion, providing longer crucible life

• More predictable performance due to consistent crucible characteristics

• Simple modular construction of coded tiles for quick assembly

• Dramatically lower labor costs and time for installation and disassembly

For more information or to receive a quote for these products, contact us today.

RELATED RESOURCES

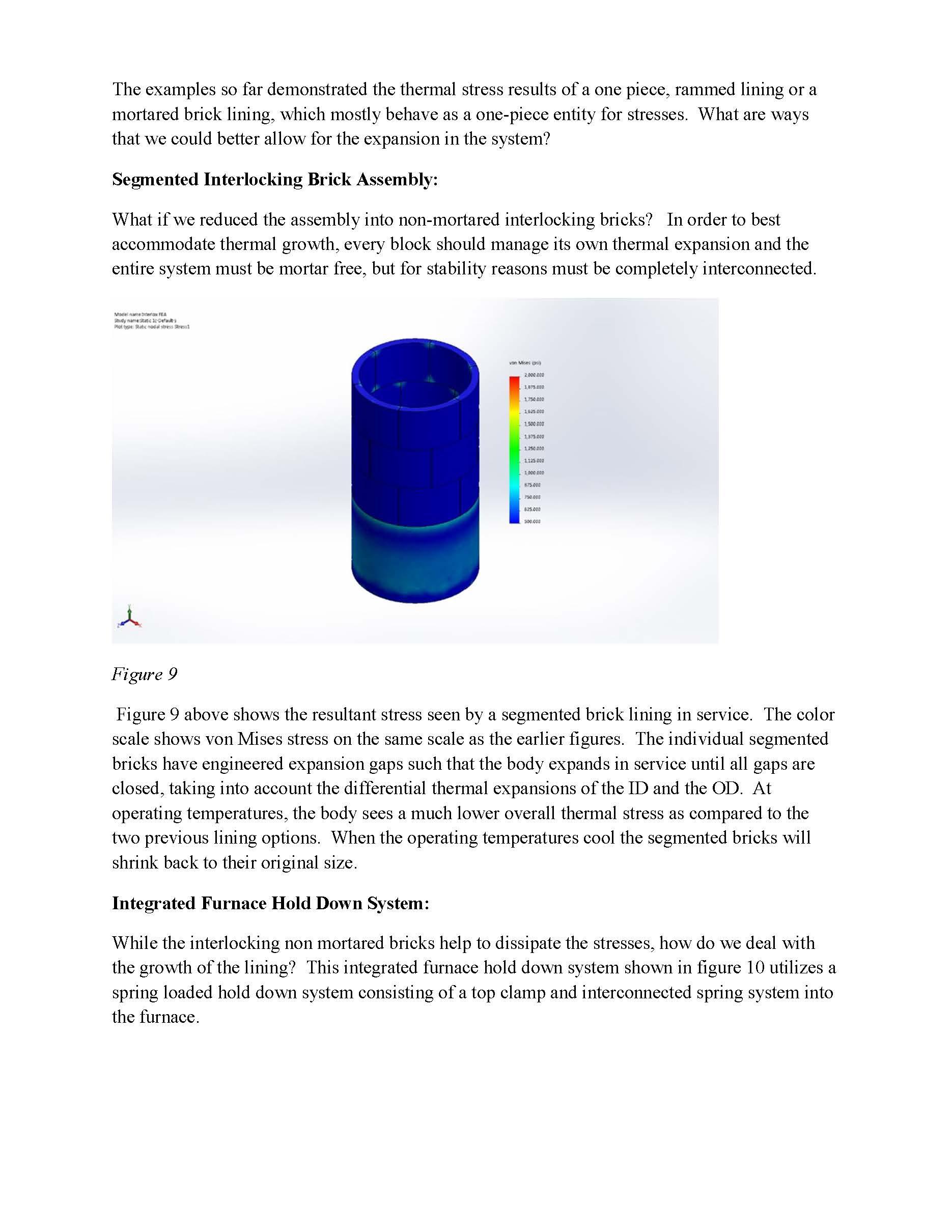

In this short video, Phil Geers, Blasch Senior Market Manager-Molten Metals, provides a product overview of the Blasch InterLok™ Segmented Crucible Lining System and its features and benefits, including its pre-designed expansion and interlocking joints that allows the entire assembly to expand and contract repeatedly through heat up and cool-down cycles.

Learn how large induction furnace lining users can benefit from the InterLok Segmented Crucible Lining Systems in this on-demand presentation by Phil Geers, including:

- Reduced thermal stresses caused by the induction melting process

- Allowing the lining to grow and contract using the integrated furnace hold-down system

Be sure to download Phil’s white paper: “Effects and Analysis of Thermal Stresses on Large Induction Furnace Refractory Linings for Molten Metal Applications”