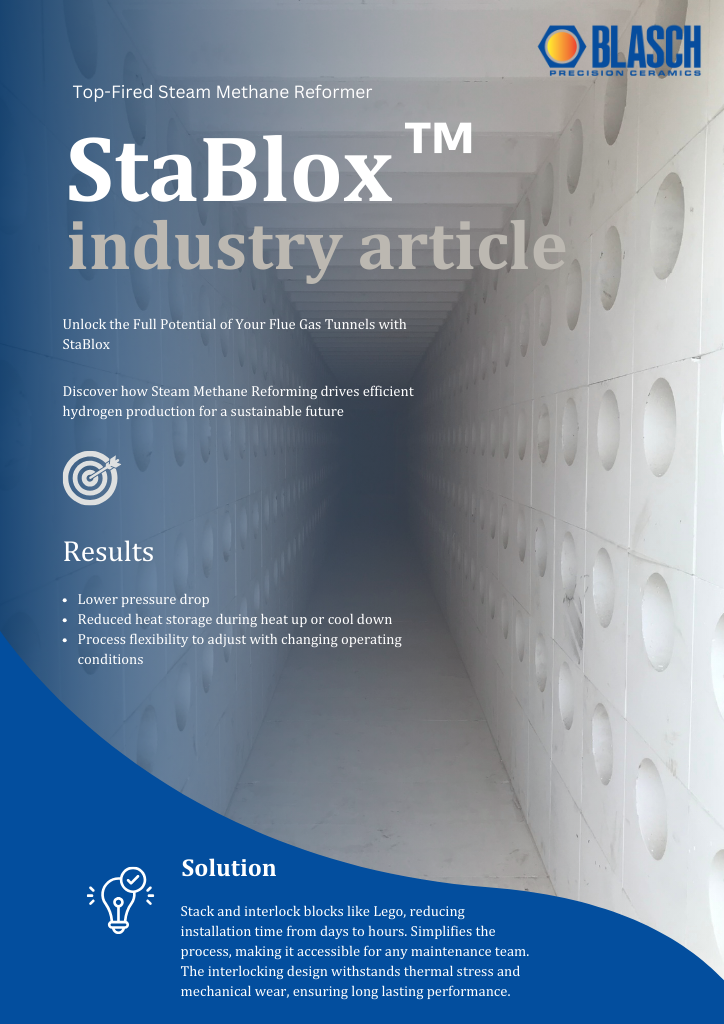

StaBlox™ Flue Gas Reformer Tunnel System for Top-Fired Steam Methane Reformer Flue Gas Tunnels

The patented Blasch StaBlox™ reformer flue gas tunnel system is a versatile, mechanically stable system consisting of a series of stackable, interlocking blocks. Unlike traditional flue gas reformer tunnels, which rely on mortar for mechanical integrity, and typically fail as a result of multiple thermal cycles and poorly performing expansion joints, the StaBlox system is designed to fit together in a mortar-free assembly that can easily and accurately accommodate for any thermal growth. Roof assemblies offer lightweight, structurally stable designs that are engineered to be much more resistant to the effects of high-temperature creep than standard designs. All StaBlox components are fully customizable allowing for any situation or unit.

U.S. Patent #10,605,456

For more information or to receive a quote for these products, contact us today.

MECHANICAL STABILITY

The unique geometry and advanced mating features of the blocks in the base, walls, tie-rods, and structural lid of the StaBlox Tunnel System allows for the assembly of complete tunnels in hours instead of the days required to fabricate a tunnel using traditional brick and mortar techniques. The highly engineered design also reduces overall mass by 60% while maintaining structural integrity.

Other mechanical advantages include, but are not limited to:

- Prefired components/no mortar required/no cure-out

- Expansion joints designed into every block

- Improved structural reliability results in less distortion and cracking

- Lower mass means less heat storage and more even cooling

- Elimination of buttresses means tunnels may be wider

PROCESS IMPROVEMENT

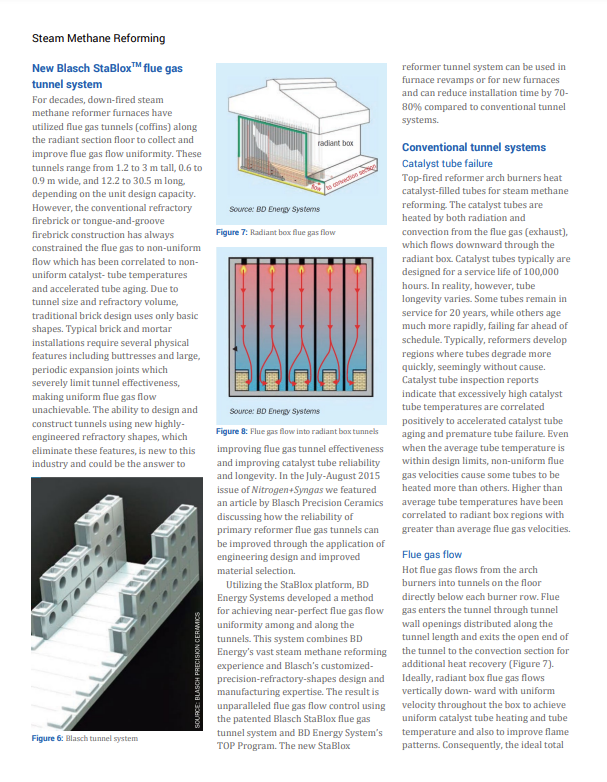

With orifice inserts, BD Energy Systems’ patented TOP™ technology may be implemented to provide near-uniform flow along the length of each tunnel, promoting even heating and reducing tube hotspots.

Other process improvements that your plant can expect to achieve include, but are not limited to:

- Reduction of methane slip of 2%-3% provides options for plant operations.

- Improved efficiency in methane conversion can provide significant savings in feedstock costs

- In situations where the plant is bottlenecked, the reduction in methane slip can result in a significant increase in plant capacity.

- Improved uniformity results in more uniform tube life, improved reliability of high-temperature components.

- Improved uniformity results in less need for individual burner adjustment to address high TMTs.

- Reduced pressure drop across the tunnel system

- Greater allowable interior tunnel width

- Increased tube reliability – Increased tunnel reliability

- Fewer emergency shutdowns – process safety improvement

- Improved SNCR NOx reduction performance

Download the Blasch Precision Ceramics and BD Energy Systems brochure.

The same base material and distributed expansion technology behind the StaBlox system have been saving Blasch customers money in various high-temperature combustion applications for decades. Tighter temperature control leads to greater conversion efficiency, and that means more product for the same amount of fuel or less fuel for the same amount of product, and less fuel means lower carbon emissions. Reduce natural gas consumption by reducing methane slip between 1%-3%, creating more uniform temperature distribution. The reduction in natural gas consumption results in substantial savings per year, not including equivalent or larger savings in carbon tax reductions or credits.

If you notice a collapsed or otherwise compromised tunnel in your reformer, Blasch maintains stock for unexpected and urgent needs. Running with a compromised tunnel greatly reduces operational efficiency. Blasch StaBlox offer faster construction and superior mechanical stability compared to traditional brick and mortar. Replacing a tunnel now is an investment in your full tunnel set later. Learn more about our Compromised Tunnel Replacement here.

Learn about how ceramic solutions like Stablox™ can boost the reliability and performance of your hydrogen production and sulfur recovery plants in this webinar!

Learn about the mechanical design and reliability features of the StaBlox™ system, and the process improvements provided by BD Energy's Tunnel Optimal Performance (TOP™) technology in this webinar.

Product Information Sheets

RELATED RESOURCES

Webpage: Blasch StaBlox Replacement Tunnels

Featuring faster, easier installation with superior mechanical stability and reduced mass compared to traditional brick and mortar. The interlocking blocks and engineered, mortar-free expansion joints ensure reliable thermal growth accommodation during operation. The absence of mortar eliminates cure time, shortening maintenance outages. The reduced mass enhances thermal efficiency, reducing thermal stress and future maintenance needs.

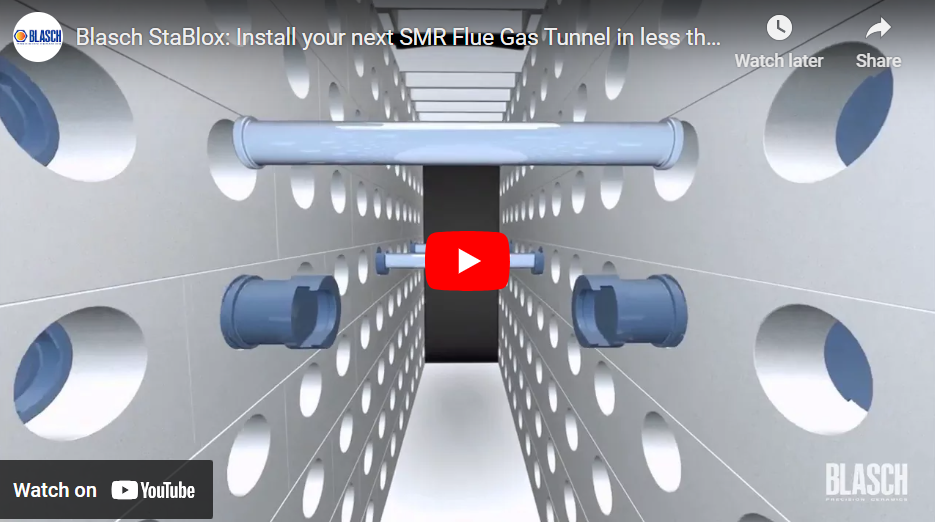

Stablox™ 3D Animation

In this short video, gain a sense of how quickly the StaBlox™ Flue Gas Reformer Tunnel system can be put together in comparison to a traditional brick-n-morter tunnel.

Guide to Sustainable Optimization in Refineries and Chemical Plants

Maximize efficiency, minimize downtime, and reduce costs with insights from the Guide to Sustainable Optimization in Refineries and Chemical Plants by Blasch Precision Ceramics. This comprehensive resource provides proven strategies and innovative solutions designed for refining, chemical processing, and industrial operations.

Article: A New Kind of Tunnel Vision

See the operating data from a 2018 installation, revealing how the Blasch StaBlox™ system and BD Energy Systems TOP™ Technology deliver uniform heating of catalyst tubes, improved heating efficiency, and extended tube life. This data further confirms these tunnels' impressive performance.

Video: StaBlox Build Demonstration

In this video, watch and see how easy it is to stack the StaBlox interlocking blocks into place to build the reformer tunnel system. The demonstration showcases the efficiency of the StaBlox design, making installation quicker and more reliable compared to traditional brick-and-mortar tunnels.

Industry Article: Improvements in Steam Methane Reforming

The breakthrough combination of Blasch StaBlox™ system and BD Energy Systems TOP™ Technology achieves near-perfect flue gas flow uniformity in tunnels. Dive into how these innovations can significantly enhance your operation's efficiency and performance.